-

Paint manufacturing industry

As a key industry in national air pollution control, the paint manufacturing industry has seen over 50 technical specifications, regulations, and other guidelines issued by domestic and international authorities and local governments as of 2019.

-

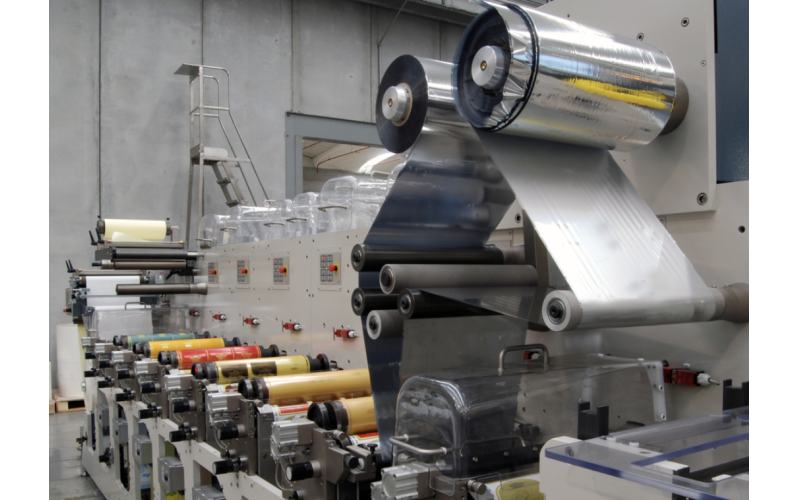

Packaging and Printing Industry

The waste gas in the packaging and printing industry mainly includes benzene derivatives, esters, alcohols, ketones, etc. With the promotion of wind reduction and concentration enhancement technology in recent years, the concentration of waste gas has gradually increased. Zeolite wheel+catalytic combustion technology or direct RTO treatment are used. However, it is common for the emission to be unstable due to fluctuations in the inlet waste gas concentration during the treatment process. In addition, the conversion rate of some RTO equipment cannot reach over 98%, which also leads to the risk of excessive exhaust gas outlet concentration. The main characteristic is a large air volume, ranging from approximately 20000m ³/h to 100000m ³/h.

-

Furniture manufacturing industry

The furniture manufacturing industry is one of the industries that involves a large amount of exhaust emissions from spray painting. Spray painting generates a large amount of organic waste gas in furniture manufacturing, but it is also one of the most important processes in the furniture manufacturing process, which directly affects the appearance, quality, and value of furniture. In the past, many companies used water washing or dust removal methods to temporarily address VOCs emissions, but the results were not satisfactory. In recent years, many industry leaders have begun to try using a combination of adsorption and catalysis processes, which have achieved very good purification effects. The main feature is that the air volume of a single production line is generally between 10000m ³/h and 30,0.

-

Transportation manufacturing industry

The transportation manufacturing industry primarily includes commercial vehicles, ships, high-speed trains, subways, heavy machinery, and aircraft manufacturing and maintenance. The exhaust gases produced during the manufacturing process are characterized by high volume and low concentration of organic compounds, and emissions are mostly intermittent.

-

Petrochemical industry

The petrochemical industry covers a wide range of applications, with diverse types of waste gases, complex operating conditions, high safety requirements, and strict demands for product lifespan and performance. Catalytic combustion technology, known for its flameless combustion and strong safety features, is highly favored by petrochemical clients. It is tailored for different waste gases, offering high selectivity in product design. This technology is commonly seen in processes such as the treatment of rubber waste gases in petrochemical applications, and similar catalytic combustion devices are used in other chemical sectors like acrylic acid and amino acid manufacturing.

-

Enameled Wire Manufacturing Industry

In the manufacturing of enameled wire, from the 1970s to the present, China has established a very large-scale capability. In the process of development, due to innovations in coating technology and the expansion of cable applications, the precision and quality requirements of enameled wire manufacturing have been increasing year by year. At the same time, due to the heavy use of solvents, the VOC emissions generated during the production of enameled wire pose increasingly daunting challenges. Owners are not only committed to reducing VOC emissions and saving energy,but also to avoiding issues such as nitrogen oxide exceedances and unorganized emissions.