Petrochemical industry

The petrochemical industry covers a wide range of applications, with diverse types of waste gases, complex operating conditions, high safety requirements, and strict demands for product lifespan and performance. Catalytic combustion technology, known for its flameless combustion and strong safety features, is highly favored by petrochemical clients. It is tailored for different waste gases, offering high selectivity in product design. This technology is commonly seen in processes such as the treatment of rubber waste gases in petrochemical applications, and similar catalytic combustion devices are used in other chemical sectors like acrylic acid and amino acid manufacturing.

Features

The waste gas composition is complex, with a wide concentration range typically from hundreds to thousands of milligrams per cubic meter.

Long-term operation requires high equipment stability and safety, with emissions including alkane gases and potentialpresence of sulfur and chlorine gases.

Specialized catalysts for methane, ethane, and propane, as well as poison-resistant catalysts, are needed.

High humidity in the waste gas necessitates long-life catalysts resistant to high temperatures and high humidity.

Common Practices

RCO

This process is a standard technology for rubber exhaust gas treatment units. Through catalytic combustion technology, the exhaust gases undergo reactions at specific temperatures to convert them into carbon dioxide and water, while utilizing the generated heat for recovery and reuse. Safety considerations primarily favor the use of RCO (Regenerative Catalytic Oxidation) over RTO (Regenerative Thermal Oxidation). Currently, major petrochemical companies in China have such installations.

CO

This process is one of thw common technologies used in chemical waste gas treatment units. It employs catalytic combustion to convert high-concentration waste gases into carbon dioxide and water, with the released heat being recycled. Due to the higher concentration of gases involved in the reaction,the typical approach is to use direct CO (Catalytic Oxidation) rather than RCO (Regenerative Catalytic Oxidation) methods.

RTO

This process is favored by many petrochemical companies due to its mature technology, high purification efficiency, and broad applicability. Under appropriate concentration conditions,Regenerative Thermal Oxidizers (RTOs) have manageable energy consumption. However, when concentrations are low, issues such as high energy consumption and excessive operating costs may arise. Additionally, during RTO operation, there is a risk of nitrogen oxide emissions exceeding standards.

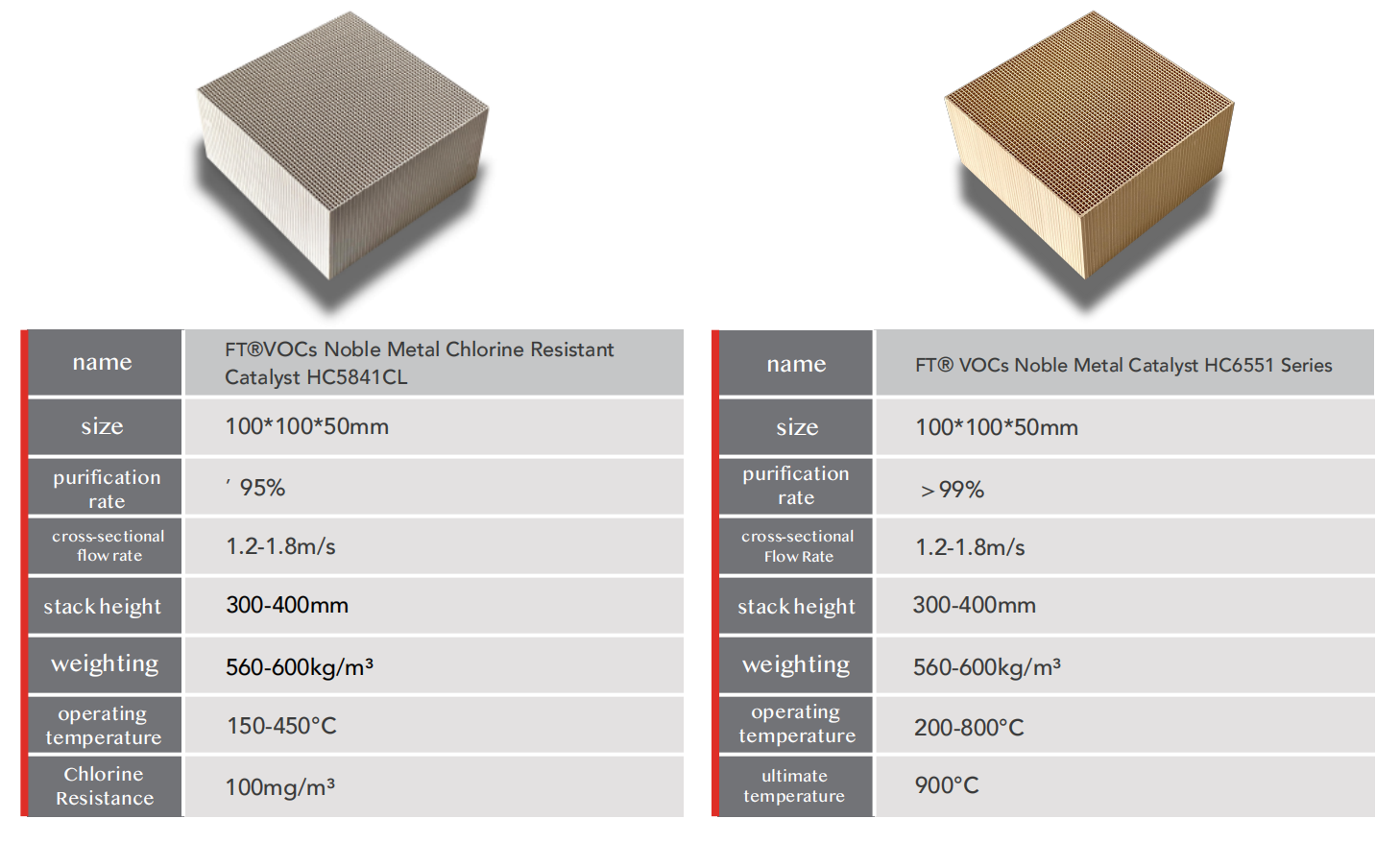

Recommended Products

New Trends

In the field of petrochemical waste gas treatment, the use of zeolite adsorption fixed beds for low-concentration waste gases in specific scenarios is emerging as a new trend. This technology replaces some of the safety hazards associated with activated carbon adsorption and desorption processes. It offers a longer lifespan and eliminates concerns about frequent replacement of activated carbon, which leads to hazardous waste disposal issues. Zeolite adsorption combined with catalytic combustion technology has become a new choice for customers in handling waste gases.

The types of waste gases in the petrochemical industry are highly complex and vary widely depending on processes and technologies. Traditional waste gas treatment technologies often fall short when faced with increasingly stringent emission requirements. Particularly, traditional activated carbon methods have long been criticized for their safety hazards. Some enterprises are exploring the use of zeolite adsorption materials to address various waste gases. By combining zeolite fixed bed adsorption with catalytic combustion and recovery technologies, they can effectively solve problems associated with various waste gases, including common VOCs, chlorine-containing or sulfur-containing gases. This approach not only meets uture higher emission standards but also enables the recycling of waste resources, turning waste into valuable materials.