Transportation manufacturing industry

The transportation manufacturing industry primarily includes commercial vehicles, ships, high-speed trains, subways, heavy machinery, and aircraft manufacturing and maintenance. The exhaust gases produced during the manufacturing process are characterized by high volume and low concentration of organic compounds, and emissions are mostly intermittent.

Features

- High air volume, approximately between 50,000 m³/h to 100,000 m³/h

- Low concentration, approximately between 10 mg/m³ to 300 mg/m³

- Large fluctuations: intermittent production leads to unstable emissions and significant variations

- Stable exhaust gas composition: the types of exhaust gases from the production line do not vary much, mainly consisting of xylene, ethyl acetate, and similar compounds

Common Practices

Activated Carbon Adsorption-Desorption + Catalytic Combustion

This process is one of the early common VOC treatment methods. Due to the strong adsorption capacity of activated carbon, it has been widely used for treating low-concentration exhaust gases.However, activated carbon is flammable, posing potential safety hazards, and has a short lifespan. Replacing it as hazardous waste is costly. Additionally, with the gradual implementation of online monitoring and high removal rate requirements, this process is restricted in some specialized industries.

- Zeolite Adsorption-Desorption + Catalytic Combustion/RTO

This process uses zeolite as the adsorption and desorption material, mainly in the forms of zeolite wheels, zeolite drums, and zeolite fixed beds for continuous adsorption and desorption. The entire system can maintain a purification efficiency of around 90% for several years. Among these, the zeolite wheel is the most widely used, suitable for continuous operation with relatively stable concentration multiples. However, it requires high pretreatment, is prone to clogging, and is difficult to maintain and regenerate. In the manufacturing process of automobiles and other transportation vehicles, water-based coatings have been implemented for some time. Many customers face challenges with outdated environmental protection equipment that cannot effectively and continuously meet online standards. Additionally, the limited concentration capacity of zeolite wheels cannot ensure the economic operation of the equipment.

Considering the market situation, FT Technology recommends using the "Zeolite Fixed Bed Adsorption Concentration + Catalytic Combustion Technology." This technology adsorbs exhaust gases using zeolite adsorbents, desorbs and burns the concentrated exhaust gases using catalytic combustion, and utilizes the generated heat energy for continuous internal circulation desorption. Since zeolite adsorbents are high—temperature-resistant porous structures, they can sustain adsorption and undergo high-temperature desorption without fire risks. During use, they can also be maintained through high-pressure gas purging and water washing.

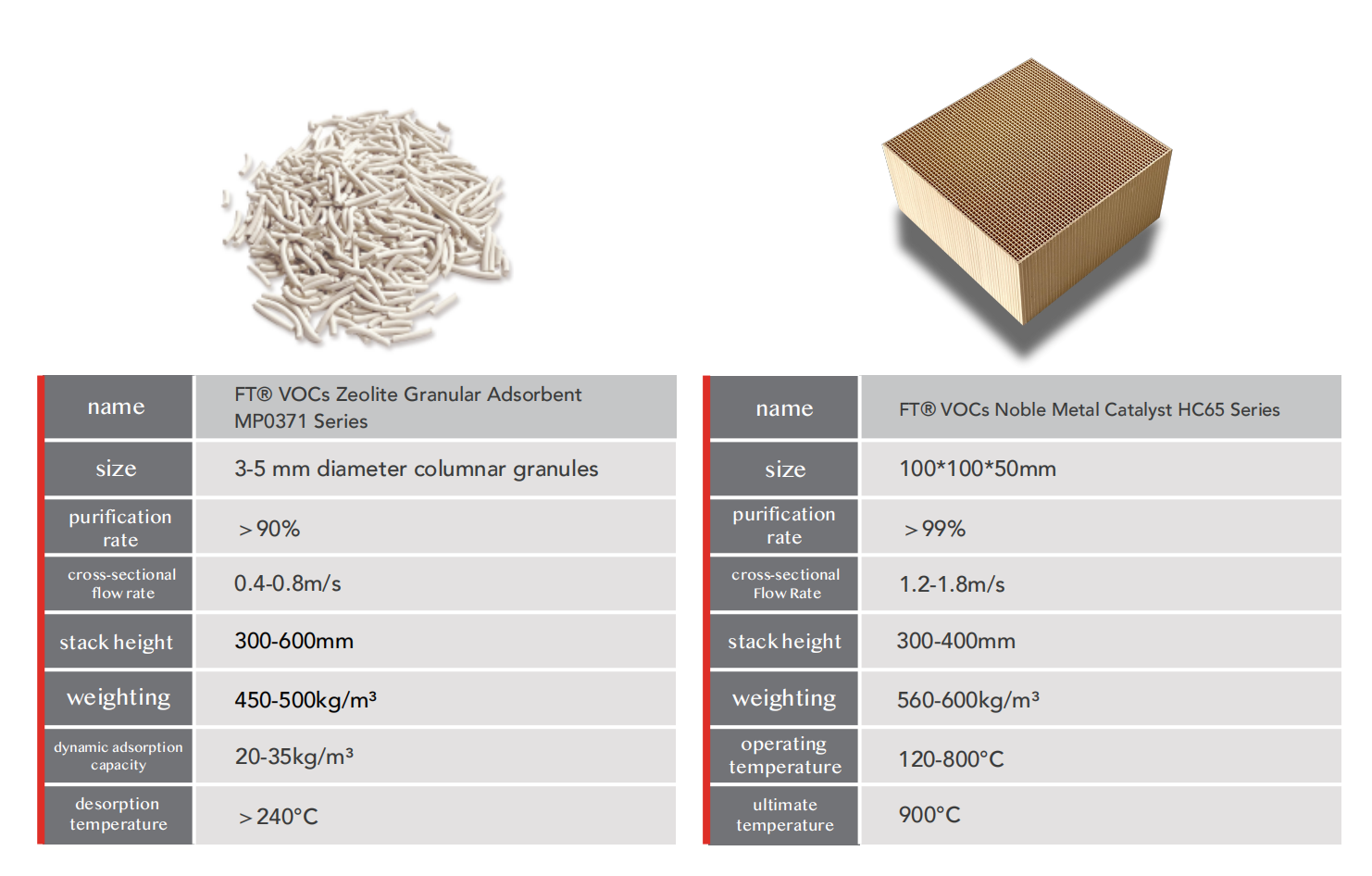

Recommended Products

New Trends

The MP0371 series of zeolite granular adsorbents is suitable for fixed-bed adsorption and catalytic combustion with zeolite, capable of adapting well to waste gases with significant concentration variations. It can maintain adsorption efficiency for extended periods and requires periodic regeneration. The HC65 series of noble metal catalysts is suitable for adsorption—desorption with activated carbon, adsorption-desorption with zeolite wheel, and adsorption-desorption with zeolite fixed—bed, all followed by catalytic combustion.

The promotion of water-based coatings has led manufacturers to face new emission challenges. Low-concentration, high—volume exhaust gases still require timely and effective treatment. At the same time, engineers must also consider the energy consumption challenges of equipment operation. Fixed-bed zeolite adsorption + catalytic combustion technology perfectly